FEA, or Finite Element Analysis, is a crucial tool used by engineers and designers to evaluate the behavior and performance of complex systems and structures. With the advent of advanced technology and the growing demand for high-performance and safe products, FEA has become an integral part of the design and engineering process.

The purpose of this article is to provide a comprehensive explanation of FEA for engineers and designers, and to help decode the mysteries surrounding this topic. This article will cover the definition of FEA, its purpose and benefits, the process of performing an analysis, and its various applications. By the end of this article, you will have a deeper understanding of what FEA is and how it can help you make informed design decisions.

Whether you are a seasoned engineer or a new designer, this article will provide valuable insights and information that will help you better understand the role and importance of FEA in the design and engineering process. So, buckle up and join us on this journey to decode the mysteries of FEA!

What is FEA?

FEA is a numerical simulation technique used to study the behavior and performance of complex systems and structures under different operating conditions. From a theoretical point of view, FEA rely on the finite element method (FEM) which seek to describe mathematically the behavior of systems and structures. FEA and FEM are made available to engineers and designers through finite element software.

The name Finite Element Analysis is derived from the fact that the simulation is performed by dividing the design into a large number of small, manageable parts, or elements. Each element is then modeled mathematically, and the interactions between the elements are analyzed to determine the response of the entire design.

In essence, FEA uses mathematical algorithms and computer software to simulate the real-world behavior of a design, and to predict its response to different operating conditions. The simulation results provide important information about the strength, stability, and durability of the design, and help engineers and designers identify areas that may require improvement.

Purpose and benefits of FEA

The primary purpose of FEA is to help engineers and designers make informed decisions about the design and performance of complex systems and structures. By using FEA, engineers and designers can:

Predict the response of the design under different operating conditions: FEA provides valuable information about the behavior and performance of a design, and allows engineers and designers to see how it will perform. This information helps to identify potential problems before they occur, and to optimize the design for improved performance, reliability, and safety.

Evaluate the strength and stability of the design: FEA provides detailed information about the stresses and strains that the design will experience, and helps to identify areas of the design that may be subject to failure. This information is critical for ensuring the design meets safety and performance requirements. By the time the Tacoma bridge was built in 1940 (see picture below) FEA was in its infancy. Would the bridge have collapsed if it had been designed using FEA? Probably not.

Save time and resources: By using FEA, engineers and designers can avoid the need for physical testing, which can be time-consuming and expensive. FEA helps to identify potential problems before they occur, saving time and resources in the long run.

Improve the overall quality of the design: FEA enables efficient evaluation of the interactions between the multiple parts of a complex system. This information helps engineers and designers to understand complex design, and leads to a higher-quality end product.

In summary, FEA is a valuable tool for engineers and designers, providing important information about the behavior and performance of complex systems and structures, and helping to optimize the design for improved performance, reliability, and safety.

FEA process

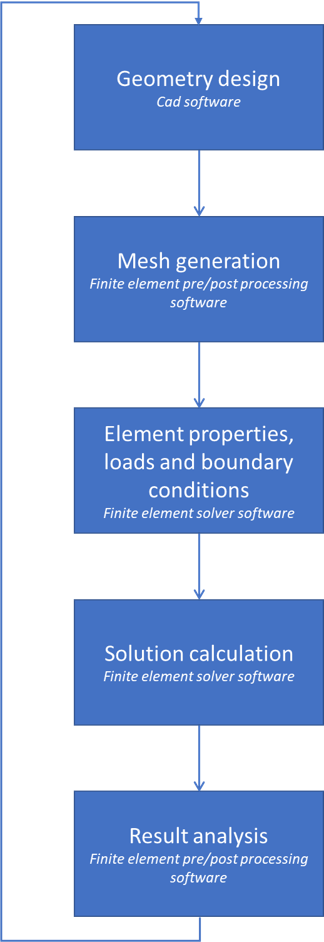

However, in order to apply FEA efficiently, you need to follow the classical analysis process described below.

Geometry creation: the first step in the FEA process is to create a computer model that represents the geometry of the system you seek to analyze. This is usually done with CAD software (for instance FreeCad). The level of detail you keep for this computer model will directly drive the prevision of the results you will get with FEA.

Mesh generation: Once the model has been created, a mesh must be generated to divide the model into smaller, manageable elements. The mesh is used to solve the equations that describe the physical behavior of the system. Meshing is usually performed using finite element pre/post processing software, as showcased is this meshing tutorial.

Elements properties definition: to describe the physical behavior of each element of the mesh, you need to assign properties on these elements. For instance, should my elements behave as a shell of 2mm thickness or do they form a slender structure which can be modeled as beam. From this step on, you start using a finite element solver like SesamX.

Loading and boundary conditions: The next step is to define the loading and boundary conditions for the analysis. This includes specifying the loads that will be applied to the model, as well as the boundary conditions that will be used.

Solution calculation: This step involves using features offered by your finite element software, to solve the equations that describe the behavior and performance of the model. This step typically requires significant computational resources, and can take several hours or even days to complete.

Results analysis: Once the solution has been calculated, the results of the analysis are displayed and analyzed. This includes displaying information about the stresses and strains that the model will experience, as well as visualizing the deformation of the model. To perform this step, you usually switch back to the finite element pre/post processing software.

Optimization and validation: Based on the results of the analysis, the design can be optimized and validated to ensure it meets performance, reliability, and safety requirements. This may involve making changes to the model, re-running the analysis, and repeating the process until the desired results are achieved. FEA is in essence an iterative process.

Application of FEA

FEA has a wide range of applications in various industries and fields, including:

Aerospace and defense: FEA is used in the aerospace and defense industries to design and test aircraft, spacecraft, and defense systems. This includes analyzing the structural integrity of airframes, engines, and other components.

Automotive Engineering: FEA is widely used in the automotive industry to design and test vehicles and their components. This includes analyzing the performance and safety of car bodies, chassis, and suspension systems.

Biomedical engineering: FEA is used in biomedical engineering to simulate the behavior of biological tissues and structures. This includes analyzing the mechanical properties of bones, muscles, and other biological tissues.

Civil engineering: FEA is used in civil engineering to design and analyze the performance of infrastructure, such as bridges, buildings, and dams. This includes simulating the behavior of these structures under different loads and operating conditions, as well as analyzing the stress and strain on these structures.

Mechanical engineering: FEA is used in mechanical engineering to design and analyze the performance of mechanical components, such as gears, bearings, and machinery.

Consumer Products: FEA is used in the design of consumer products, such as appliances, electronics, and toys. This includes making sure that the products does not break easily while dropped and that it does not hurt its user.

In summary, FEA has a wide range of applications in various industries and fields.

Conclusion

FEA is a powerful tool that helps engineers and designers optimize designs for improved performance, reliability, and safety. By using computer simulations to analyze the behavior of structures and systems under different operating conditions, FEA provides valuable insights into the strengths and weaknesses of designs. This allows engineers and designers to make informed decisions and improve their designs before they are built and tested.

In this article, we have provided a comprehensive overview of FEA, including its definition, purpose, benefits, process, and applications. Whether you are a seasoned engineer or a newcomer to the field, we hope that this article has helped to demystify the world of FEA and inspired you to explore its many applications. If you seek to go one step further, you can read more about the finite element method itself.

In conclusion, FEA is an essential tool for engineers and designers who want to create high-quality, reliable, and safe designs. Whether you’re working in aerospace, automotive engineering, biomedical engineering, civil engineering, mechanical engineering, or another field, the benefits of FEA are clear. So, if you are not already using FEA in your work, we encourage you to give it a try and see the results for yourself!

Did you like this content?

Register to our newsletter and get notified of new articles